ACTIFLO® Disc is a polishing solution designed to achieve high removal levels of suspended solids and phosphorus in municipal and industrial wastewater for water reuse.

Overview

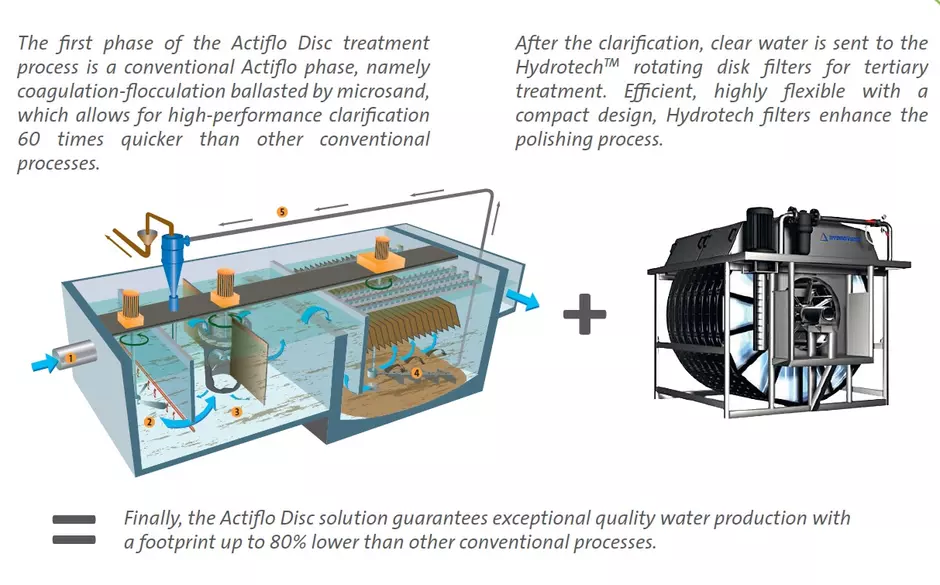

Actiflo® Disc’s configuration combines two efficient and compact treatment processes: a conventional Actiflo® phase, namely coagulation-flocculation ballasted bu microsand which allows for high-performance clarification, followed by a rotating disk filter polishing system for tertiary treatment.

With a total removal rate in excess of 95% for phosphorus and up to more than 99% for suspended solids, Actiflo Disc’s performance exceeds most discharge and reuse standards.

Benefits

- Very compact solution, easy to adjust to present facilities or sites to be refurbished.

- Compactness: a footprint up to 80% lower than other conventional processes.

- Very low water losses

- Provides a protective barrier against parasites (ex: Helminth eggs).

- Lower turbidity, suspended solids and reduces residual phosphate contents.

- Gravity filtration

- Continuous supply with no shutdown to wash filters

Applications

Thanks to its unique equipment design, ACTIFLO® Disc is applicable in several industrial and municipal situations.

Municipal applications

- Pre-treatment upstream of the membrane to produce drinking water

- Wastewater treatment

- Tertiary wastewater treatment for reuse in irrigation, replenishing the groundwater table or for urban use.

Industrial applications

- Industrial wastewater treatment

- Production of process water

- Wastewater treatment for reuse

Some Municipal References

Municipal wastewater/Reuse

- El Prat (Baix Llobregat), Barcelona, Spain, 2006, 346,000 m3/day Tertiary treatment for reuse, aquifer recharge, irrigation, urban cleaning, salt wedge and in industry

- Camp Tarragona (Tarragona), Spain, 2010, 30,000 m3/ day - Tertiary treatment for reuse as process water and coolant in the chemicals industry

- Hefei Binhu Beilaowei (Ph. I), China, 2014,30 000 m3/dayTertiary treatment, settling velocity

- Manawatu District Council, Feilding WWTP, New Zealand, 2013, 7,500 m3/day Tertiary treatment of biological filtration effluents

- TOM Prinsenland, Dinteloord, Netherlands, 2013, 2,400 m3/day pre-treatment of effluents and surface water upstream of an “RO”, reuse for greenhouse irrigation

Municipal potable water

- Harpeth Valley UD, Nashville, TN, USA - 90,000 m3/day, (2015)

Some Industrial References

Industrial reuse /process water

- Bäckhammars Bruk, Kristinehamn, Sweden, 2002, 48,000 m3/day Treatment of river water to produce Pulp & Paper process water

- Mankato, USA, 2006, 54,000m3/day Tertiary treatment for reuse as boiler water at the Calpine plant

- Vale, (Inco) Goro Nickel, New Caledonia, France, 2008, 70,000 m3/day

- Polishing treatment of mine effluents for disposal in sensitive natural environments.

- Corning Japan, Japan, 2010, 500 m3/day Primary treatment of effluents for microelectronics sector

- Stratford Peaker Power Project , Taranaki, New Zealand, 2010, 6,000 m3/day River water treatment for process water production

- Philips Lumileds, Bayan Lepas (Penang), Malaysia, 2012, 800 m3/day, Primary treatment of effluents for microelectronics sector, reuse as process water