Hubgrade Wastewater Plant Performance is a digital solution that optimizes wastewater treatment plants for municipal and industrial applications. Empowered by real-time data, analytics, and artificial intelligence, our digital solution continuously optimizes your plant operations, helping you achieve significant cost savings, minimize environmental impact, and comply with regulations.

What challenges do you want to overcome?

Unlock the power of digital twin for a smart wastewater management

Hubgrade Wastewater Plant Performance is an online digital twin of the wastewater treatment plant. It creates a digital representation of your plant which uses predictive analysis and data to provide in real time optimized setpoints to the PLC control and deliver insight to operators, process engineers and management.

Hubgrade Wastewater Plant Performance optimizes wastewater operations of municipal and industrial customers all over the world.

Decarbonate and reduce the environmental footprint

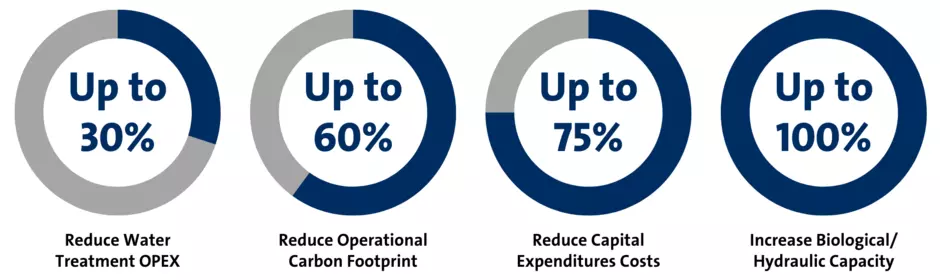

Wastewater treatment processes contribute to greenhouse gas emissions, energy, and chemicals consumption. It is therefore crucial for utilities to improve their environmental footprint. Hubgrade Wastewater Plant Performance reduces the overall carbon footprint of your plant by up to 60%.

The Klaipeda wastewater treatment plant, located in Lithuania, has reduced its carbon footprint drastically by -2180 T CO2-eq/year, while improving its effluent performance.

Discover how Hubgrade Wastewater Plant Performance helped Klaipeda’s facility to reduce its greenhouse gases emissions.

LEARN MORE >

- Reduce N2O emissions by up to 70%

- Reduce electricity expenses on aeration by up to 30%

- Decrease total-Nitrogen and total-Phosphorus in effluent by up to 60%

- Reducing the carbon footprint of electricity by 30% by prioritizing when the electricity is green

Optimize operational and capital investments to achieve cost savings

Wastewater treatment utilities face significant financial challenges such as price inflation, chemical shortages, load increase making investment optimization a top priority. Hubgrade Wastewater Plant Performance reduces your capital expenditure costs by up to 100%, as well as up to 30% of your daily operational costs.

- Reduce investment related to the expansion of your wastewater treatment plant by up to 100%

- Reduce energy expenses by up to 30%

- Reduce chemical consumption by up to 100%

- Enhance hydraulic capacity in biological step by up to 100%

- Increase biological capacity by up to 60%

Find out how this Danish wastewater treatment plant was able to save 35% of its energy costs while increasing its hydraulic capacity by 100% during rain events.

LEARN MORE >

Ensure high level of water quality to comply with stringent regulations

Wastewater treatment is a critical process supervised by stringent regulations to avoid risks to public health and environmental degradation. Hubgrade Wastewater Plant Performance ensures your facility compliance by continuously monitoring effluent quality, providing real-time alerts, applying predictive analytics and issuing automated reports for regulatory submissions.

- Reduce effluent quality taxes by up to 30%

- Prevent WWTPs bypasses by up to 100%

- Reduce combined sewer overflows (CSO) by up to 75%

- Forecast and anticipate heavy rainfall to give more data-driven control to operators

Discover how, since 2011, the Ede WWTP faced a load increase of 38% over a 10 year period and still reached the EU’s strict quality standards with Hubgrade Wastewater Plant Performance.

LEARN MORE >