Idrapress™ has been designed for the conveyance and dewatering of various types of wastewater screenings and it is capable to reduce drastically the screenings weight and volume and consequently transport and disposal costs.

Overview

The dewatering of the screenings separated by various types of coarse and fine solids screens, drum or channel screens is a real need in all municipal and industrial WWT Plants for reduction of the screenings volume and hygienic management.

The screenings can be humid/viscid, pasty and/or sticky, plug and bridge forming and for this reason the dewatering can be difficult and always different problem to solve.

Application

Idrapress™ is used for dewatering of screenings from municipal WWT Plants, slaughteries, food industries and agriculture, paper mills, etc.

Applications

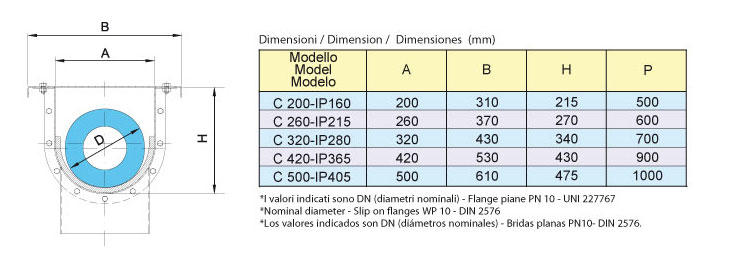

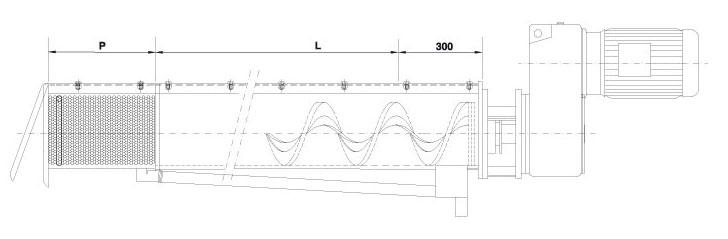

The screenings are collected in a hopper having size and dimensions properly suitable for Idrascreen model it is serving. From here the screenings are fed into the sturdy, flexible, shaftless screw in big thickness special steel. The screw is provided by just one support at the drive end and no other supports. The screenings are conveyed up to the pressing area equipped with drainage basket.

The dewatering is operated by the screw in the drainage basket friction area by means of an adjustable counterpressure clapet. The gearbox operates in pushing arrangement, no mechanical parts in contact with the handled material and this allows max reliability. As the Idrapress™ is totally closed the conveyance of screenings is hygienic and it is possible to equip the press with a continuous bagging system.